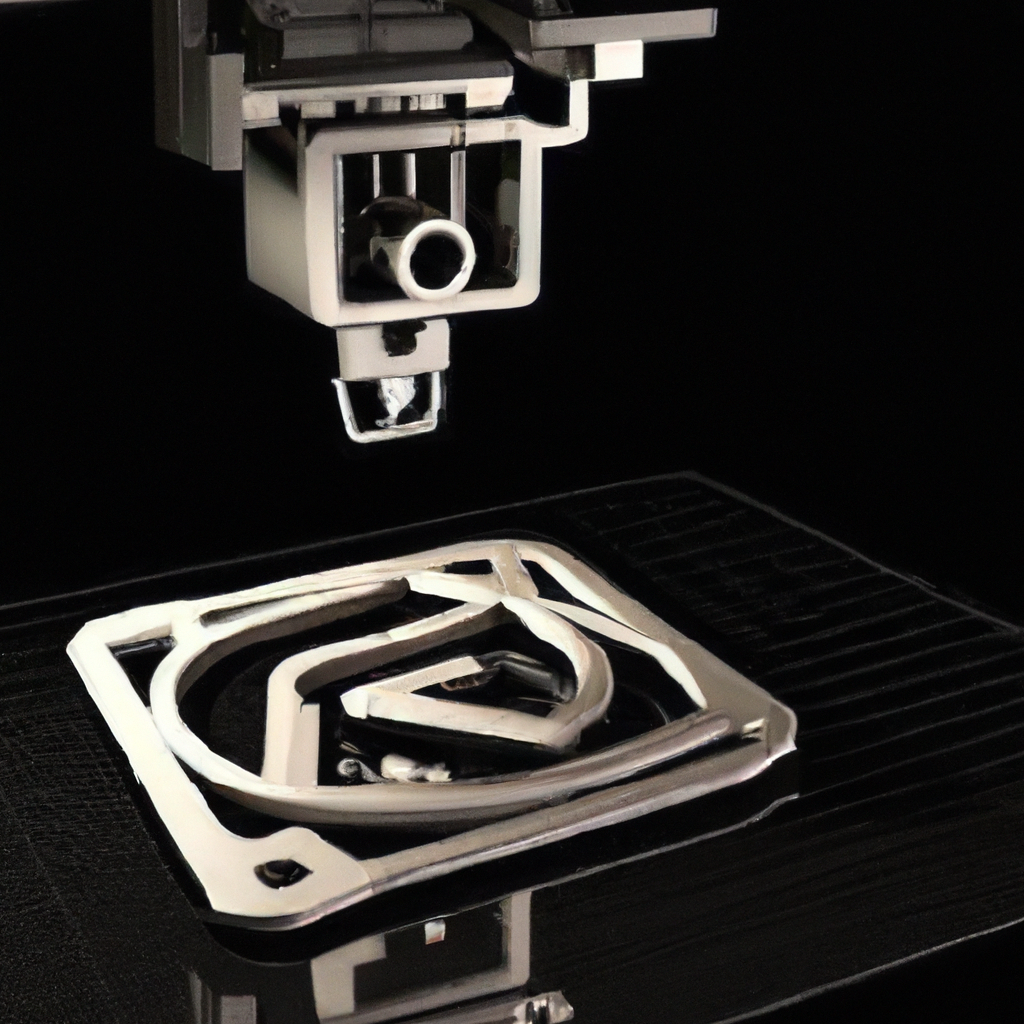

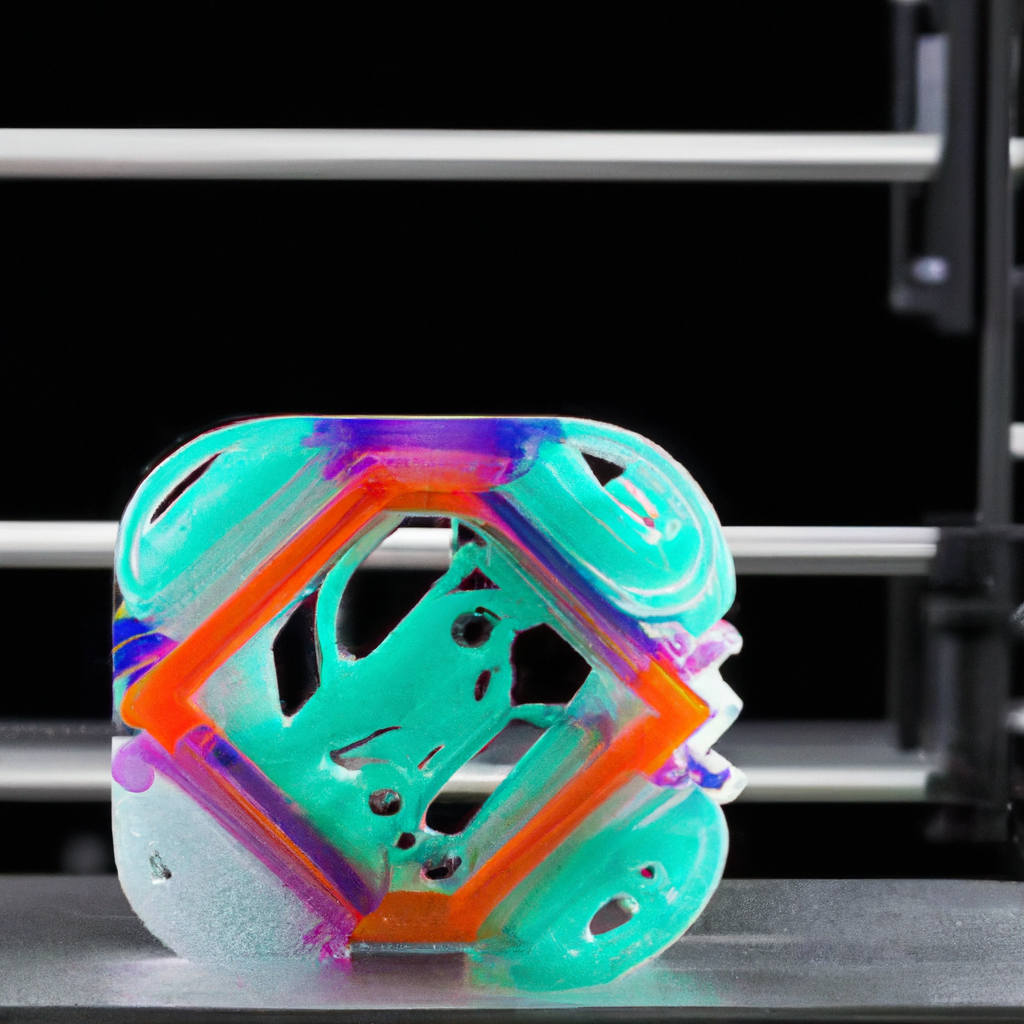

Imagine a world where objects can be created at the touch of a button, where a simple design on a computer screen can transform into a physical, tangible item. This is the reality that 3D printing is bringing to industries everywhere. From medicine to aerospace, 3D printing is revolutionizing the way products are made and opening up a whole new realm of possibilities. In this article, we will explore the expanding horizons of 3D printing in industries and discover the incredible potential it holds for innovation and advancement.

Introduction

Welcome to the world of 3D printing, where the boundaries of imagination are being pushed further than ever before. Over the past few decades, 3D printing has made significant strides, revolutionizing various industries and unlocking a realm of endless possibilities. This cutting-edge technology has the potential to transform the way we create, manufacture, and innovate across a range of sectors. From the automotive and aerospace industries to healthcare and fashion, 3D printing has sparked a new era of customization, efficiency, and sustainability. So let’s dive into the exciting world of 3D printing and explore the incredible potential it holds for various industries.

1. Automotive Industry

Revolutionizing prototyping and design

Gone are the days of painstakingly creating physical prototypes by hand. With 3D printing, automotive manufacturers can now quickly and cost-effectively produce intricate and accurate prototypes. This not only speeds up the design process but also allows for more iterations and improvements before moving into production. By 3D printing prototypes, automakers can test the functionality, fit, and aesthetics of various components and make necessary adjustments without the need for expensive and time-consuming tooling.

Customization of parts and components

One of the most significant advantages of 3D printing in the automotive industry is the ability to customize parts and components. From interior elements like dashboard panels and door handles to exterior components like grilles and spoilers, 3D printing enables automakers to create unique and personalized designs. This customization potential extends beyond aesthetics, allowing for tailored performance enhancements and optimized functionality specific to each vehicle or customer.

Streamlining the supply chain

Traditionally, the automotive supply chain has been complex and time-consuming, with parts and components often outsourced from various suppliers. However, 3D printing has the potential to streamline this process by allowing manufacturers to produce parts on-site and on-demand. By reducing dependencies on external suppliers, automakers can minimize production delays, reduce costs, and increase overall efficiency. Furthermore, 3D printing enables the creation of spare parts for legacy vehicles, eliminating the need for expensive inventory management and warehousing.

2. Aerospace Industry

Lightweight and complex designs

The aerospace industry demands lightweight yet robust designs, and 3D printing has emerged as a game-changer in this regard. By utilizing advanced materials and intricate printing techniques, aerospace engineers can create complex and lightweight structures that were previously impossible to manufacture. This not only reduces the weight of aircraft, leading to fuel efficiency and reduced carbon emissions but also enhances performance and safety.

Reducing costs in manufacturing

Aerospace manufacturing is known for its high costs, but 3D printing has the potential to change this paradigm. By eliminating the need for complex tooling and reducing material waste, 3D printing allows for significant cost savings in the production of parts and components. Moreover, the ability to produce parts on-demand eliminates the need for excessive inventory management and storage, further reducing overhead expenses.

Improving efficiency in maintenance and repairs

Maintenance and repair operations are critical in the aerospace industry, where safety and reliability are of utmost importance. 3D printing has proven to be a valuable tool in this domain, allowing for the rapid production of replacement parts and reducing aircraft downtime. With the ability to produce customized spare parts quickly and cost-effectively, airlines and maintenance providers can ensure faster turnaround times, thus minimizing disruptions and improving operational efficiency.

3. Healthcare Industry

Personalized prosthetics and implants

3D printing has made significant strides in the healthcare industry, particularly in the field of prosthetics and implants. By utilizing patient-specific measurements and creating personalized designs, 3D printing enables the production of custom-fitted prosthetics and implants that are both comfortable and functional. This technology has revolutionized the lives of amputees and patients requiring implants by offering enhanced mobility, comfort, and quality of life.

Biofabrication and tissue engineering

The field of biofabrication and tissue engineering has been greatly advanced by 3D printing. This technology allows for the creation of complex and intricate structures using living cells, giving rise to the potential for organ transplantation and tissue regeneration. By layering bioinks composed of living cells, biomaterials, and growth factors, scientists and researchers can create functional tissues and organs that closely resemble their natural counterparts. This groundbreaking approach has the potential to revolutionize organ transplantation, eliminate long waiting lists, and save countless lives.

Enhanced medical training and education

Medical training and education have greatly benefitted from the integration of 3D printing. Surgeons can now utilize patient-specific 3D-printed models to simulate complex procedures and pre-plan surgeries, leading to improved precision and better patient outcomes. Medical students also reap the benefits by having access to accurate anatomical models for hands-on learning, allowing them to develop essential skills and gain a deeper understanding of the human body. The integration of 3D printing in medical education has the potential to enhance the quality of healthcare professionals and ultimately improve patient care.

4. Architecture and Construction

Creating intricate models and prototypes

Architects and designers are now embracing 3D printing as a powerful tool for creating intricate models and prototypes. This technology enables them to transform their digital designs into physical representations, allowing for a better understanding of spatial relationships, scale, and visual aesthetics. By 3D printing architectural models, professionals can iterate, experiment, and refine their designs more efficiently, ultimately leading to better final results.

Customized building components

The construction industry is rapidly adopting 3D printing to create customized building components. From intricate facades and decorative elements to functional structural components, 3D printing allows for the production of unique and complex designs that cannot be achieved through traditional construction methods. This technology offers architects and builders the freedom to unleash their creativity and deliver highly customized and visually appealing structures.

Sustainable and eco-friendly construction

In addition to customization and design flexibility, 3D printing also presents significant opportunities for sustainable and eco-friendly construction practices. By utilizing recycled materials and optimizing material usage through precise 3D printing, the construction industry can reduce waste and minimize its environmental footprint. Furthermore, 3D printing allows for the creation of innovative design solutions that promote energy efficiency and environmentally conscious building practices.

5. Fashion and Textile Industry

Print-on-demand production

The fashion and textile industry has witnessed a revolution with the advent of 3D printing. This technology facilitates print-on-demand production, enabling designers to create custom garments and accessories without the need for large-scale manufacturing. With 3D printing, designers can bring their intricate and avant-garde designs to life, catering to niche markets and individual preferences. This shift towards sustainable and on-demand production helps reduce waste and inventory surplus in the fashion industry.

Design innovation and experimentation

3D printing has unlocked a new realm of design innovation and experimentation in the fashion and textile industry. Designers can now explore new materials, textures, and structures that were previously impossible to achieve with traditional manufacturing processes. From intricate lace-like patterns to detailed and embellished accessories, 3D printing allows for the creation of unique and unconventional fashion pieces that push the boundaries of what is possible.

Reducing waste and environmental impact

Sustainability has become a key focus in the fashion industry, and 3D printing plays a significant role in reducing waste and minimizing the environmental impact. By producing garments and accessories layer by layer, 3D printing eliminates the need for excessive fabric cutting and reduces material waste. Additionally, this technology enables the use of recycled materials and biodegradable filaments, further enhancing its eco-friendly potential.

6. Food Industry

Personalized nutrition and dietary needs

3D printing is revolutionizing the way we think about food by enabling personalized nutrition and catering to specific dietary needs. With the ability to create customized food products based on individual requirements, 3D printing provides a solution to the challenges of mass food production. This technology allows for precise control over ingredient composition and portion sizes, making it possible to create personalized meals that meet specific nutritional needs or accommodate dietary restrictions.

Enhancing food presentation and aesthetics

Food presentation is an essential aspect of culinary experiences, and 3D printing offers chefs and food enthusiasts exciting possibilities for enhancing aesthetics. By creating intricate and detailed designs using edible materials, 3D printing allows for the creation of visually stunning culinary creations that are sure to impress. From decorative garnishes and intricate chocolate sculptures to personalized cake toppers, this technology elevates the artistry and presentation of food.

Creating complex and intricate culinary designs

The intricate and complex designs made possible by 3D printing extend beyond aesthetics and presentation. Chefs and food innovators can create entirely new culinary experiences by designing innovative textures, shapes, and structures. From intricately layered desserts to unique pasta shapes, 3D printing opens up a world of possibilities for culinary creativity and experimentation.

7. Electronics and Consumer Goods

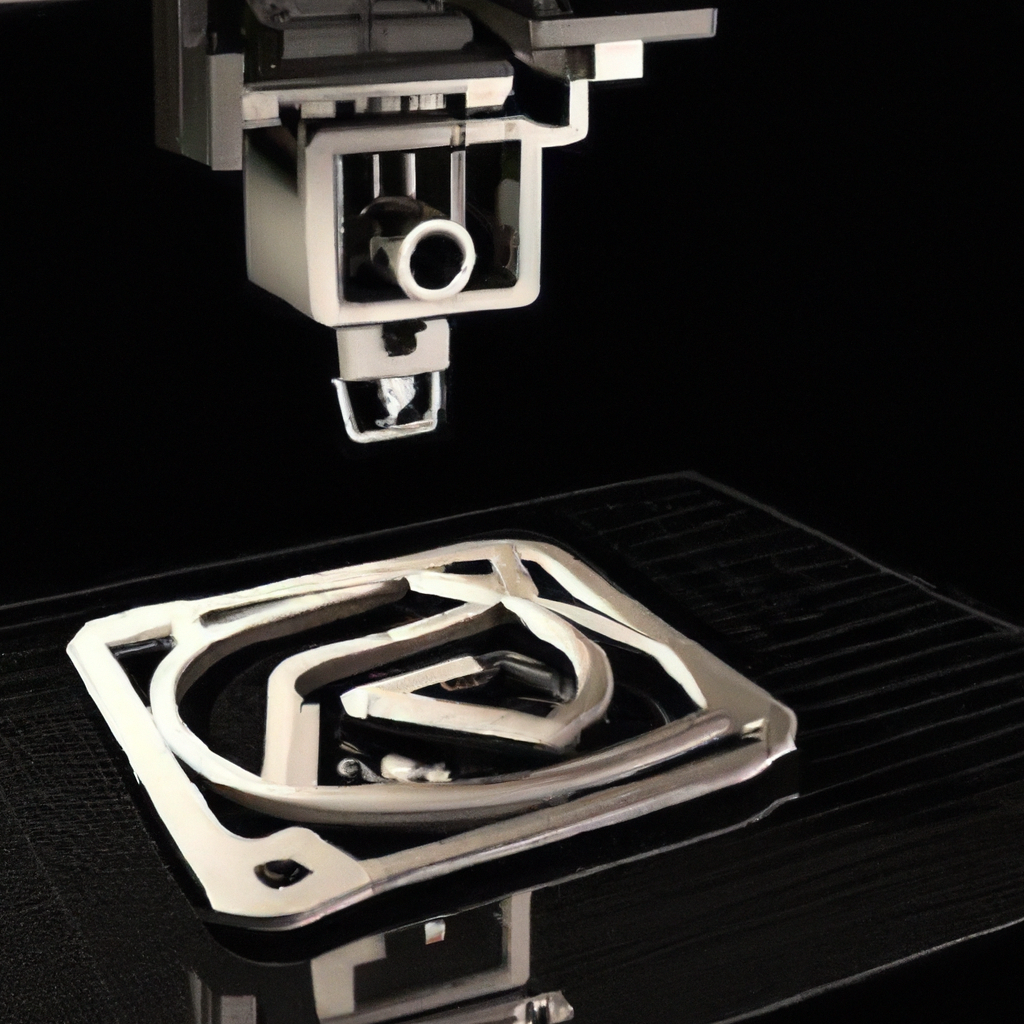

Rapid prototyping and innovation

The fast-paced world of electronics and consumer goods greatly benefits from the rapid prototyping capabilities of 3D printing. Innovators and entrepreneurs can bring their ideas to life quickly and cost-effectively, iterate and refine their designs, and ultimately accelerate time to market. This technology allows for the creation of functional prototypes that can be tested for performance, usability, and aesthetics, enabling designers to optimize their products based on real-world feedback.

Miniaturization of components

As electronic devices become smaller and more complex, 3D printing offers a solution for the miniaturization of components. With the ability to create intricate and precise structures in a single print, 3D printing enables the production of high-quality and miniaturized electronic components. This technology plays a vital role in industries such as microelectronics and robotics, where size and precision are crucial for optimal performance.

Tailored and customizable products

The era of mass production is giving way to tailored and customizable products, and 3D printing is at the forefront of this trend in the electronics and consumer goods industries. From personalized phone cases and accessories to custom-fit wearable devices, 3D printing allows for the creation of products that cater to individual preferences and requirements. This shift towards customization enhances user experience and satisfaction, ultimately leading to increased customer loyalty and brand differentiation.

8. Energy and Sustainable Solutions

Advanced modeling and simulation for renewable energy

The energy sector heavily relies on accurate modeling and simulation to optimize the performance of renewable energy systems. 3D printing plays a crucial role in this process by allowing engineers to create scaled-down physical models that accurately represent real-world conditions. These models help researchers and engineers assess the performance, efficiency, and economic feasibility of renewable energy solutions, enabling the development of more reliable and sustainable systems.

Optimization of energy systems

3D printing offers immense potential for the optimization of energy systems by enabling the creation of advanced and customized components. By utilizing intricate design features and reducing material waste, this technology allows for the production of highly efficient and lightweight parts for energy systems. From wind turbine blades and solar panels to fuel cells and batteries, 3D printing contributes to the development of clean and sustainable energy solutions.

Development of functional prototypes for clean technologies

Clean technologies and innovations require functional prototypes for testing and validation, and 3D printing provides a versatile and cost-effective solution. By quickly producing prototypes with complex geometries and internal structures, researchers and innovators can accelerate the development of clean technologies. This approach allows for iterative improvements, ensuring that clean technologies achieve optimal performance and reliability before scaling up to commercial production.

9. Education and Research

Hands-on learning and experimentation

3D printing has become an invaluable tool in education, allowing students of all ages to engage in hands-on learning and experimentation. From elementary schools to universities, this technology enables students to bring their ideas to life, fostering creativity, critical thinking, and problem-solving skills. Whether it’s designing and printing a simple object or creating complex scientific models, 3D printing empowers students to explore, tinker, and learn in a tangible and exciting way.

Prototype development for scientific research

In scientific research, 3D printing offers researchers the ability to develop prototypes for various experiments and investigations. This technology allows scientists to create custom lab equipment, models, and tools tailored to their specific research needs. By 3D printing prototypes, researchers can iterate and refine their designs, accelerate their experiments, and ultimately contribute to advancements in various scientific fields.

Access to affordable educational resources

3D printing opens up new avenues for accessible and affordable educational resources. By enabling the production of educational materials, models, and tools on-demand, this technology reduces the cost and barriers to accessing quality educational resources. From anatomical models for biology classes to geography maps and historical artifacts, 3D printing enhances the learning experience and facilitates a deeper understanding of complex concepts.

Conclusion

As we wrap up our exploration of the expanding horizons of 3D printing in industries, it is clear that this technology has revolutionized various sectors and is poised to continue shaping the future of manufacturing, healthcare, construction, and beyond. The potential of 3D printing knows no bounds, offering customization, efficiency, sustainability, and innovation like never before. Whether it’s revolutionizing prototyping in the automotive industry, enabling personalized healthcare solutions, empowering innovative designs in fashion, or propelling advancements in renewable energy, 3D printing has proven itself to be a game-changer. So, embrace this technology and get ready to unlock a world of endless possibilities, where your imagination is the only limit to what you can create.