Imagine a world where materials have the astonishing ability to transform themselves, opening up a realm of endless possibilities. This is the future of 4D printing. As advancements in technology continue to revolutionize the way we create and manufacture objects, scientists and engineers are exploring the potential of materials that can not only be 3D printed, but also possess the remarkable ability to change shape or adapt to different conditions over time. In this article, we will take a closer look at the incredible potential of 4D printing and delve into how it may revolutionize various industries, from healthcare to infrastructure. Get ready to be amazed by the extraordinary capabilities of this cutting-edge technology.

Understanding 4D Printing

Concept of 4D Printing

Have you ever imagined a material that can transform itself over time, adapting to its environment and changing its shape without any external forces? That’s the essence of 4D printing. Building upon the principles of 3D printing, 4D printing takes it to a whole new dimension by introducing the element of time. It involves the creation of objects using smart materials that can self-assemble, self-repair, or change their properties in response to external stimuli. The fourth dimension in 4D printing refers to the material’s ability to transform itself over time, revealing its full potential.

Difference between 3D and 4D Printing

While 3D printing revolutionized the manufacturing industry by enabling the creation of complex three-dimensional objects, 4D printing takes it a step further by introducing dynamic and autonomous transformations. The key difference lies in the materials used. In 3D printing, objects are created layer by layer using a wide range of materials such as plastics, metals, and ceramics. On the other hand, 4D printing utilizes smart materials that can respond to external stimuli like heat, moisture, or light, allowing for self-transformation. By incorporating the fourth dimension of time, 4D printing opens up new possibilities for creating objects with adaptive and programmable functionalities.

Brief History of 4D Printing

The concept of 4D printing originated in the early 2010s when researchers at MIT’s Self-Assembly Lab began experimenting with self-transforming materials. It was here that the term “4D printing” was coined. In 2013, a team led by Professor Dr. Jennifer Lewis at Harvard’s Wyss Institute developed the first self-folding 4D structures using shape-memory polymers. Since then, numerous breakthroughs have been made in the field, with researchers and engineers exploring the potential of 4D printing in various industries. Today, 4D printing has evolved from a mere concept to a rapidly developing technology with promising applications in fields such as medicine, construction, and design.

The Science behind Self-Transforming Materials

The Role of Smart Materials

At the heart of 4D printing lies the use of smart materials. These materials have the ability to respond to environmental cues and change their properties accordingly. Shape-memory polymers, hydrogels, and programmable composites are some examples of smart materials commonly used in 4D printing. Shape-memory polymers have the unique ability to return to their original shape after being deformed, making them ideal for creating objects that can self-transform. Hydrogels, on the other hand, can swell or shrink in response to changes in moisture, allowing for shape changes. Programmable composites integrate multiple materials with different transformation properties, enabling complex shape-shifting structures.

Embedding Transformation Properties

To enable self-transformation, these smart materials need to be programmed with transformation properties. This is achieved through careful engineering and the incorporation of additives or stimuli-responsive molecules that control the material’s behavior. For example, shape-memory polymers are first deformed into the desired shape and then locked into that shape through a process called programming. When exposed to a stimulus like heat or light, the material undergoes a phase change, releasing it from its temporary shape and allowing it to revert back to its programmed shape. By controlling the programming parameters and the stimuli, engineers can precisely control the timing and extent of the material’s transformation.

Understanding Reshapeable Polymers

Another class of smart materials used in 4D printing is reshapeable polymers. These polymers have the innate ability to be reshaped multiple times without losing their structural integrity. Traditional polymers often degrade when subjected to repeated deformations, limiting their applications. Reshapeable polymers, however, have a unique molecular structure that allows them to undergo significant reshaping while maintaining their strength and durability. These materials hold immense potential in industries such as aerospace and automotive, where the ability to repeatedly reshape components could revolutionize design and manufacturing processes.

Current Applications of 4D Printing

Medicine and Biotechnology

The field of medicine has embraced the transformative potential of 4D printing. Researchers and surgeons are exploring how self-transforming materials can enable personalized medical devices and implants. For example, 4D printed stents can be designed to dynamically change shape based on the patient’s anatomy, leading to improved effectiveness and reduced complications. In the realm of biotechnology, 4D printing offers exciting possibilities. Researchers are working on biofabrication techniques that involve printing living cells and materials that can self-organize into functional tissues or organs. This has the potential to revolutionize tissue engineering and regenerative medicine, offering new hope for patients in need of organ transplants.

Construction and Infrastructure

In the construction industry, 4D printing is revolutionizing the way buildings and infrastructure are designed and built. Self-transforming materials can enable structures that adapt to changing environmental conditions, such as responsive facades that open or close based on the weather. These materials can also be used to create self-healing concrete, which has the ability to repair cracks and extend the lifespan of infrastructure. Additionally, 4D printing enables the creation of complex and customized architectural components, reducing material waste and allowing for innovative designs that were once deemed impossible.

Design and Art

4D printing is also making waves in the world of design and art. Artists and designers are exploring the creative possibilities offered by self-transforming materials. With 4D printing, they can bring dynamic and interactive elements to their creations, blurring the lines between art, design, and technology. From sculptures that change shape or color in response to light, to clothing that adapts to the wearer’s body temperature, 4D printing opens up a world of possibilities for designers and artists to create captivating and immersive experiences.

Advancements in 4D Printing Technology

Progress in Material Science

Continuous advancements in material science play a crucial role in the development of 4D printing technology. Researchers are constantly exploring new materials and formulations to enhance the capabilities of self-transforming materials. For instance, the development of stimuli-responsive materials that can undergo multiple transformations or exhibit more sophisticated shape changes is a promising area of research. Furthermore, recent breakthroughs in bioinks, a type of printable biomaterial, have paved the way for biofabrication techniques that could revolutionize the field of tissue engineering.

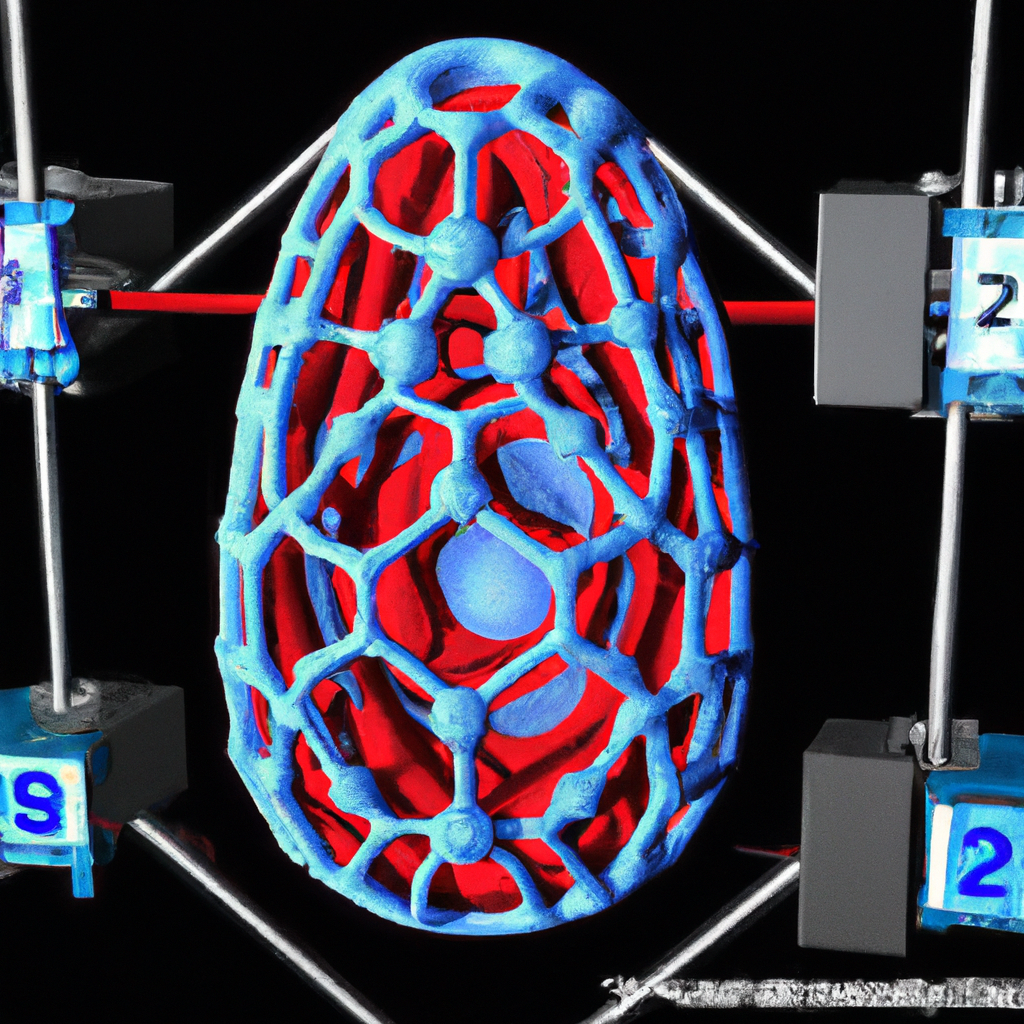

Improvements in Printing Techniques

Printing techniques have also seen significant advancements to facilitate the fabrication of complex, self-transforming structures. Traditional 3D printers are being modified or developed specifically for 4D printing purposes, allowing for the precise deposition of smart materials layer by layer. Additive manufacturing techniques, such as multi-material printing and multi-nozzle extrusion, are being utilized to enable the integration of different materials within a single printed object. This enables the creation of objects with varying transformation properties, enhancing the functionality and versatility of 4D printed structures.

Data Modeling and Computation Advances

The digital aspect of 4D printing is equally important as the physical fabrication process. Data modeling and computational tools are integral in designing and simulating the behavior of self-transforming materials. Advanced software can simulate the material’s response to different environmental stimuli and predict its transformation properties. This allows engineers to optimize the design, performance, and functionality of 4D printed objects before physically fabricating them. By leveraging computational tools, researchers can accelerate the development process and unlock new possibilities in the field of 4D printing.

Challenges in the Sphere of 4D Printing

Constraints in Material Science

While material science is rapidly advancing, there are still challenges to be overcome in the development of smart materials for 4D printing. One challenge lies in finding materials that can endure repeated transformations without degradation or fatigue. Additionally, the development of stimuli-responsive materials that can exhibit precise and controllable shape changes remains a complex task. Addressing these material constraints is crucial to unlock the full potential of 4D printing and enable the creation of highly functional and durable self-transforming objects.

Implementation Difficulties

The implementation of 4D printing technologies is not without its share of difficulties. The fabrication process requires precise control over various parameters, including temperature, humidity, and stimulus exposure. Ensuring consistency and accuracy throughout the printing process is a challenge that researchers and engineers are actively tackling. Furthermore, scaling up the technology to enable large-scale production presents its own set of challenges. Overcoming these implementation difficulties is vital to make 4D printing accessible and commercially viable for widespread applications.

Cost and Economic Factors

As with any emerging technology, cost and economic factors come into play. The production of smart materials and the specialized equipment required for 4D printing can be expensive, limiting its accessibility for many industries. The cost of research and development, as well as the complexity of the fabrication process, can add up to a significant investment. Additionally, the integration of 4D printing into existing manufacturing workflows may require additional training and infrastructure, adding to the overall cost. Overcoming these economic barriers is essential to ensure the widespread adoption and commercial success of 4D printing.

The Future of 4D Printing

Predicted Growth and Development

The future of 4D printing appears bright and filled with exciting possibilities. With continuous advancements in material science, printing techniques, and computational tools, we can expect to see significant growth and development in the field. Researchers are already exploring new frontiers, such as developing materials that can sense and respond to multiple stimuli, or designing structures with hierarchical transformations. As technology matures and becomes more accessible, it is anticipated that 4D printing will revolutionize industries ranging from healthcare to aerospace, unlocking unprecedented design and manufacturing capabilities.

Potential Sectors for Use

The potential applications of 4D printing span across various sectors. In healthcare, self-transforming medical implants, tissue engineering, and drug delivery systems hold great promise. The construction industry stands to benefit from the creation of adaptive structures, self-repairing infrastructure, and sustainable building materials. Design and art can continue to push boundaries with dynamic and interactive creations. Other potential sectors for 4D printing include aerospace, automotive, consumer goods, and electronics, where the ability to create objects with adaptive functionalities can revolutionize product design and performance.

Role in Sustainable and Green Technologies

4D printing has the potential to play a significant role in advancing sustainable and green technologies. By reducing material waste through optimized designs and complex geometries, 4D printing can minimize the environmental impact of manufacturing processes. The use of biofriendly materials and biofabrication techniques can contribute to the development of sustainable solutions in fields like medicine and biotechnology. Furthermore, the ability of 4D printed structures to adapt and self-repair can lead to longer-lasting products, reducing the need for frequent replacements and ultimately reducing waste.

Impact of 4D Printing on Society

Shaping Consumer Behavior

As 4D printing becomes more prevalent and accessible, it has the potential to profoundly shape consumer behavior. The ability to customize and personalize products to an unprecedented level can lead to a shift in consumer preferences. Consumers may start valuing products that can adapt to their changing needs or offer unique interactive experiences. This could have implications for traditional supply chains and manufacturing processes, as companies may need to adopt more flexible and responsive production models to meet the evolving demands of consumers.

Influence on Job Markets and Economy

The widespread adoption of 4D printing technology is likely to have an impact on job markets and the economy. While it may eliminate some traditional manufacturing jobs, it will also create new opportunities in research, design, engineering, and maintenance of 4D printing systems. The development and production of smart materials, as well as the customization and post-processing of 4D printed objects, can lead to the emergence of new job roles. Furthermore, the economic potential of 4D printing can contribute to economic growth and the development of new industries centered around this transformative technology.

Ethical and Safety Implications

As with any emerging technology, 4D printing raises ethical and safety considerations. The ability to create objects that can self-transform can have implications in various fields. In medicine, ethical concerns may arise when it comes to the use of 4D printed implants or biofabricated tissues. Ensuring the safety, efficacy, and long-term effects of these transformative materials is of utmost importance. Additionally, issues related to intellectual property rights and the regulation of 4D printing need to be addressed to mitigate potential misuse or unethical practices.

Regulations and Policies in the 4D Printing Field

Current Regulatory Landscape

As 4D printing technology continues to evolve, regulations and policies need to keep pace to ensure safety and quality standards. Currently, the regulatory landscape for 4D printing is still in its nascent stages, and existing regulations for traditional manufacturing processes may not fully encompass the unique characteristics of 4D printed objects. Regulatory bodies and policymakers are now beginning to address these challenges by developing guidelines and standards specific to 4D printing. Collaboration between researchers, industry stakeholders, and regulatory agencies is essential to establish a robust framework that ensures the responsible development and use of 4D printing technology.

Future Legal Considerations

As 4D printing becomes more prevalent, legal considerations related to intellectual property rights and liability may come to the forefront. The ability to create objects with adaptive functionalities raises questions about ownership and patent protection. Protecting the designs, algorithms, and software used in 4D printing will be crucial to spur innovation and prevent unauthorized replication. Additionally, the question of liability arises when it comes to 4D printed objects that can change their shape or properties unpredictably. Developing clear legal frameworks that address these considerations will be essential for the responsible growth of the 4D printing industry.

Role of Intellectual Property Rights

Intellectual property rights play a critical role in incentivizing innovation and protecting the interests of inventors and creators. In the context of 4D printing, intellectual property rights become even more important. The ability to create objects with dynamic properties opens up new challenges in terms of protecting designs and controlling the manufacturing process. Developing robust intellectual property frameworks that balance the need for innovation and collaboration while safeguarding the rights of inventors and designers is essential to foster continued advancements in 4D printing technology.

Investments and Market Opportunities in 4D Printing

Current Market Overview

The market for 4D printing is still emerging, but it holds significant potential for growth. Currently, various industries such as healthcare, construction, and design are actively investing in research and development of 4D printing technologies. Companies ranging from startups to established players in the manufacturing sector are exploring the potential applications of 4D printing and investing in the necessary infrastructure and expertise. The market is witnessing collaborations between academia, research institutions, and industry, fostering innovation and driving the commercialization of 4D printing.

Potential Economical Upswing

The economic impact of 4D printing is expected to be significant. As the technology matures, it has the potential to disrupt traditional manufacturing processes and unlock new opportunities. The ability to create objects with adaptive functionalities can lead to improved product performance and reduced maintenance costs, resulting in economic savings for industries such as healthcare, aerospace, and automotive. Furthermore, the customization and personalization capabilities of 4D printing can cater to niche markets and drive consumer demand. This opens up opportunities for entrepreneurial ventures and economic growth in the 4D printing sector.

Investment Opportunities

With the increasing interest and potential in 4D printing, investment opportunities are emerging in various areas. Venture capitalists and angel investors are actively seeking opportunities to invest in startups and companies that are developing innovative 4D printing technologies and materials. Additionally, research and development funding from government agencies and private organizations is driving advancements in the field. Investors looking for long-term growth and innovation can explore opportunities in 4D printing technology, materials development, software solutions, and end-use applications.

Conclusion: The Transformative Potential of 4D Printing

The future of manufacturing lies in the transformative potential of 4D printing. By incorporating the element of time into the fabrication process, 4D printing enables the creation of objects that can self-assemble, self-transform, or self-repair. With advancements in material science, printing techniques, and computational tools, the possibilities for 4D printing are expanding at a rapid pace. From personalized medical devices to adaptable infrastructure, 4D printing holds immense promise in revolutionizing industries and opening up new avenues for creativity and innovation.

However, challenges such as material constraints, implementation difficulties, and cost considerations need to be overcome for the widespread adoption of 4D printing. Collaborative efforts between researchers, industry stakeholders, and policymakers are crucial in addressing these challenges and establishing a robust framework that ensures the responsible development and use of 4D printing technology.

As 4D printing continues to evolve, it will shape consumer behavior, impact job markets and the economy, and raise ethical and safety implications that need to be addressed. Regulatory bodies and policymakers need to keep pace with technological advancements, developing guidelines and legal frameworks specific to 4D printing. Additionally, protecting intellectual property rights and fostering investments in the 4D printing industry are vital for its continued growth and development.

In conclusion, 4D printing has the potential to redefine the manufacturing paradigm, contribute to a sustainable future, and unlock possibilities that were once unimaginable. Its transformative capabilities and applications across various sectors make 4D printing a technology to watch out for. As we move forward, the scope and impact of 4D printing are likely to exceed our expectations, making it an exciting field with boundless potential.